In the present world, technology is the most essential part of human life. These machines and appliances are necessary to survive a single day properly. From a small pin to a vast ship, everything is technology. The industries factories which are establishing with new modern machinery are introducing.

But the crucial part of an industry is the machines that help them manufacture the products for which the industry is known. The machines must be accurate and efficient to have the same result every time.

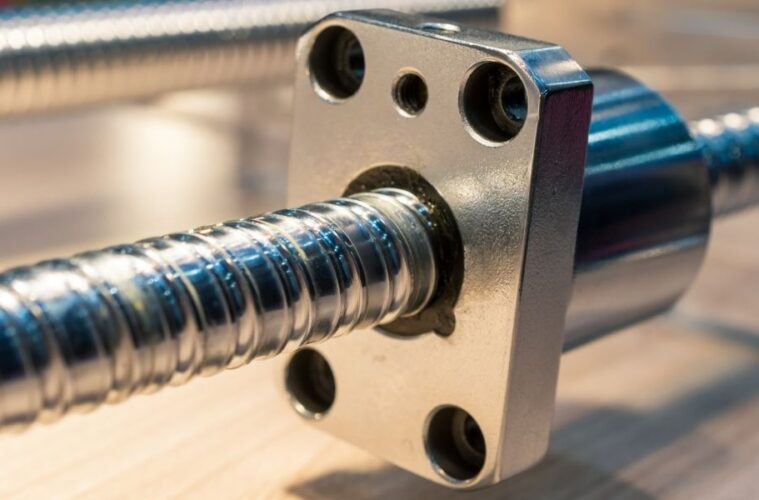

There are several parts of the machine are there which combine to make it a machine like Ball screw BLK (บอลสกรู BLK, which is a term in Thai), Bearings, and many other essential parts also.

In this article, we will go to discuss ball screws which play a vital role in the industries. So, let us begin.

How Many Types of Ball Screws Are There?

Ball screws are the elements that convert the rotational motion into smooth and linear motion with very low friction.

There are some types of ball screws present, which we are going to discuss below:

· Rolled Thread Ball Screws:

This is the most cost-effective technique for making a screw. It is a type of screw made without harming any material, but a complex steel thread is fitted in the desired place to form a screw. In contrast, they do not deliver much accuracy and precision in comparison to the other type of ball screws but are effective with some kind of work.

· Ground Ball Screws:

These screws are also made by rolling the hard steel, but the cutting of material takes place to make them more precise and zero mistake appearance. These are the best suitable screws for the high accurate and reliable work.

· Precision Ball Screws:

They are just similar to their name. These screws are made to deliver an excessive amount of accuracy and linear motion in the machinery system in industries where no negative response is tolerable, and precision is the most important thing. They also play a vital role in aircraft, spacecraft, manufacturing, and medical appliance industries.

· Miniature Ball Screws:

These ball screws are relatively used in industries where less space, accuracy, and precision are essential. They are manufactured to provide accuracy and linear motion, with small size basically for small machinery systems.

· Stainless Steel Ball Screws:

These ball screws convert rotational motion into smooth and linear motion, with having property of corrosion-resistant, which makes them different from others. They are commonly used in machinery systems in various industries like medical appliances, marine equipment, etc, where durability and rust resistance properties are necessary.